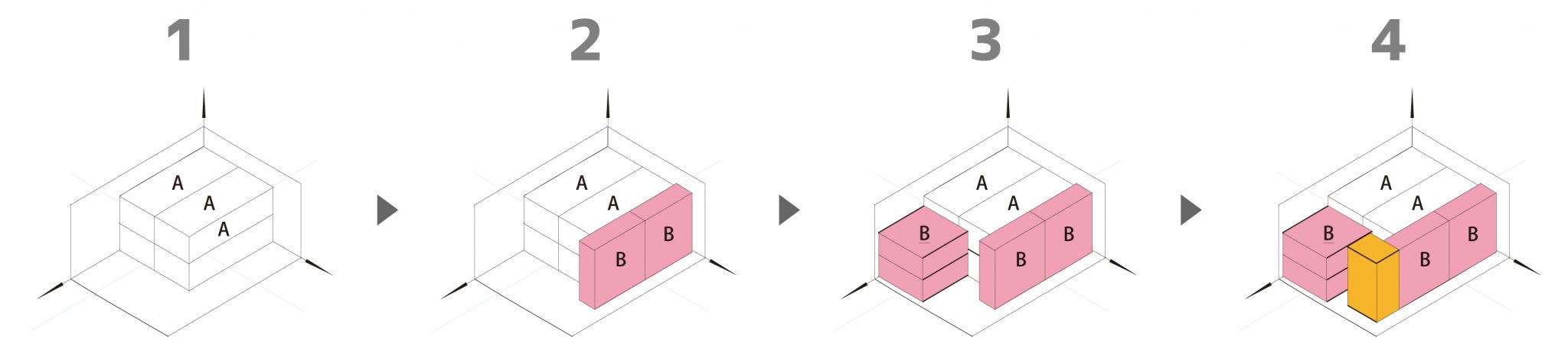

About loading order

Loading order can be specified for each product.

By setting the “loading order” at the planning stage, you can visualize the space to be used and adjust the quantity of materials.

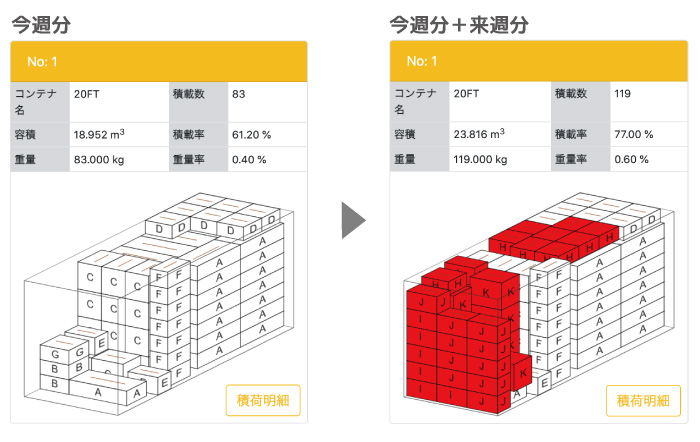

It can also be used in cases where there are different loading and multiple unloading locations.

Example: Distinguish loading order for this week and next week

How to set the loading order from the screen

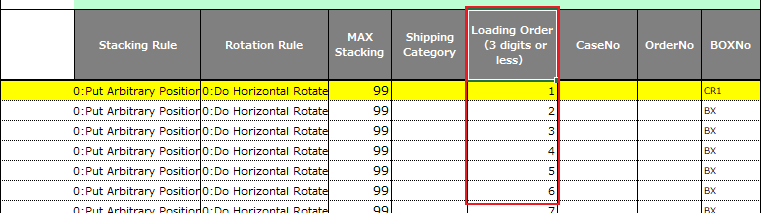

If loading order is not specified, products are loaded in order from the back of the container.

For products to be placed near the door (e.g., dangerous goods), specify a large number such as “9” in the “Loading Order” (The larger the number, the closer the product will be placed to the front).

“Shipping Category” is used to indicate the grouping of loading order.

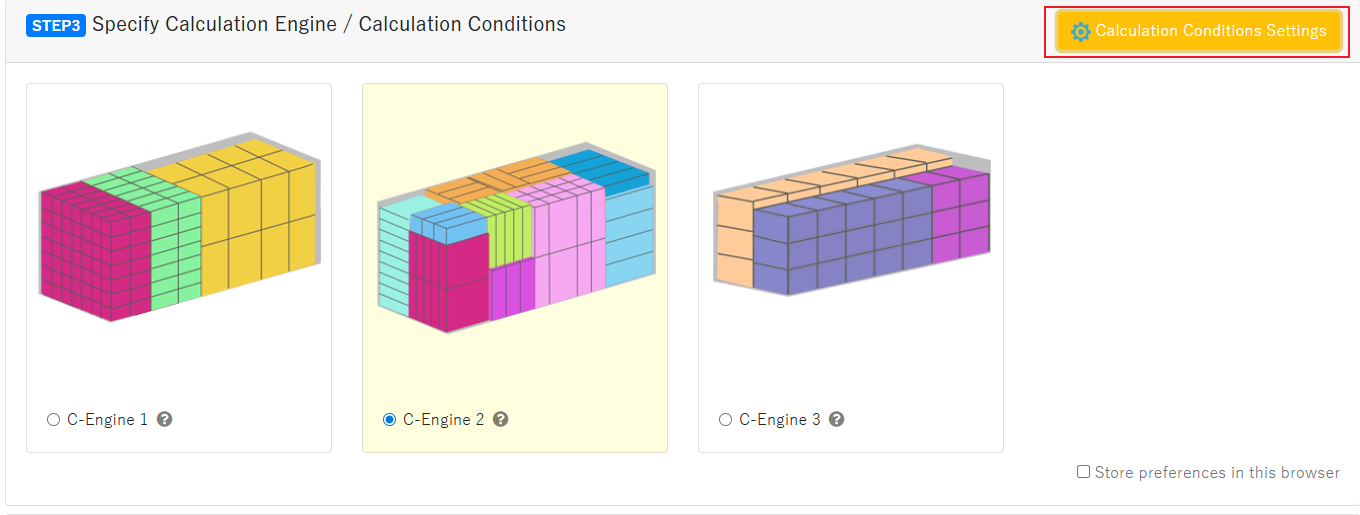

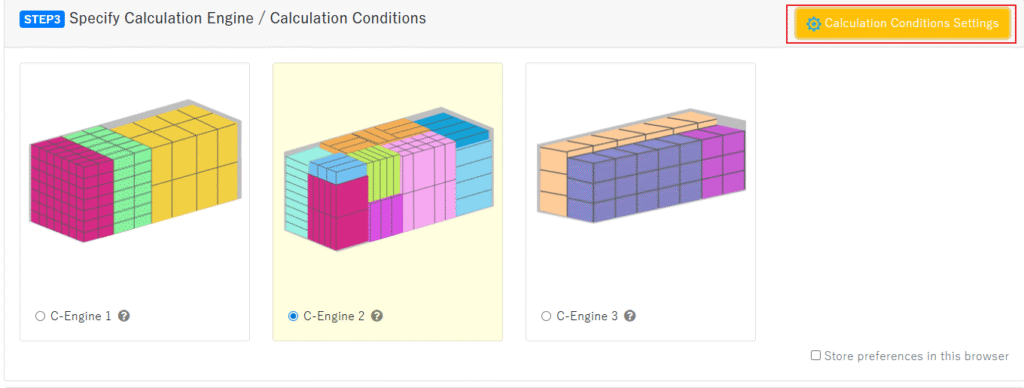

The loading order setting is valid when “C-Engine 2” or “C-Engine 3”.

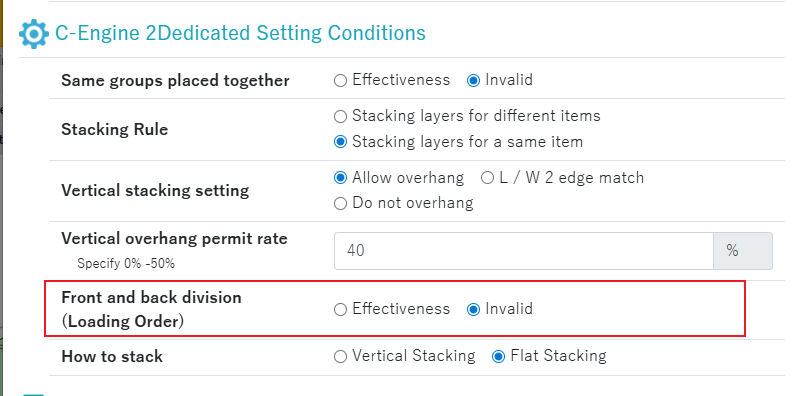

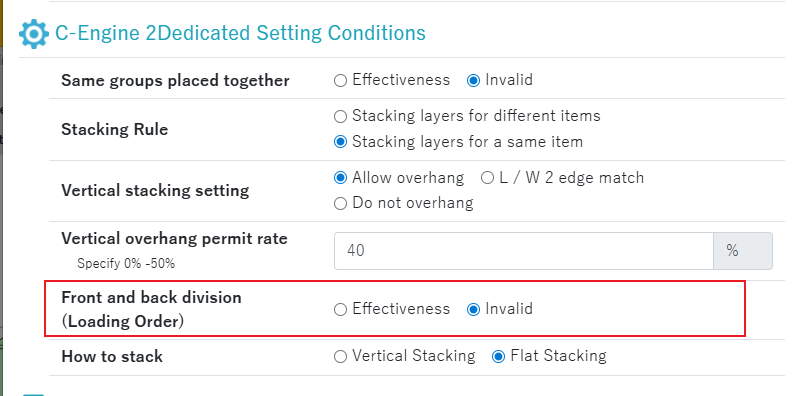

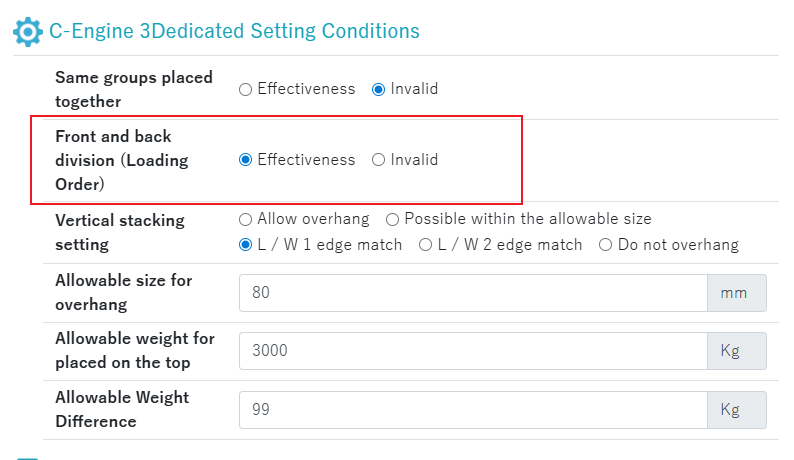

The loading order can be set on the “Calculation Condition Settings” screen.

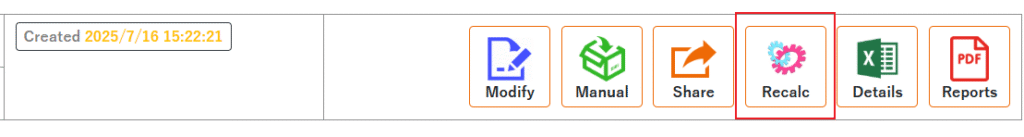

※If you want to change the settings after the calculation, execute “Recalc” screen.

C-Engine 2

C-Engine 3

How to set the loading order from “Create Simulation Data”

If loading order is not specified, products are loaded in order from the back of the container.

For products to be placed near the door (e.g., dangerous goods), specify a large number such as “9” in the “Loading Order” (The larger the number, the closer the product will be placed to the front).

“Shipping Category” is used to indicate the grouping of loading order.

The loading order setting is valid when “C-Engine 2” or “C-Engine 3”.

The loading order can be set on the “Calculation Condition Settings” screen.

※If you want to change the settings after the calculation, execute “Recalc” screen.